Bombardier P-Line

OLE Foundation Installation

By the time ESL mobilised to site the project had already encountered several delays in the design process meaning that completing the works has swiftly as possible was critical. We were able to trial hole and complete the installation of eight concrete foundations within a week allowing our client to recover their programme and land OLE masts on schedule.

We carried out trial holes at each of the foundation locations. This was particularly important given the number of unidentified services that were running throughout the site and which had to be carefully moved clear of our foundation positions.

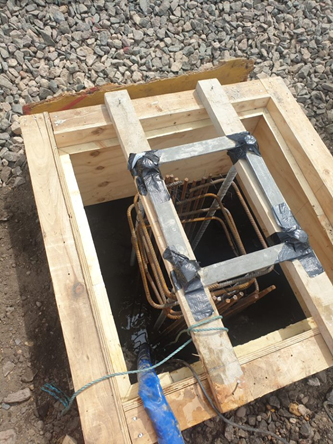

The main foundation methodology consisted of auguring with RRVs, installing a pre-built rebar cage and filling the foundation with concrete using an RRV fitted with a clam shell bucket. Due to the compressed programme we installed all eight foundations in a single shift, a great achievement from our site team. Their work was made more difficult as the manufacturing facility was fully operational during our works, meaning we had to carefully integrate our movements around what was happening on the site.

Following the foundation installation our team stripped and rubbed up the foundations, whilst our engineers completed final quality assurance to ensure there would be no difficulty landing the OLE steel. To provide further reassurance to our client, we attended site during the steel installation shift so that if any unexpected difficulties arose, we had a presence available to provide advice and rectification.

The project was completed successfully and to the satisfaction of our client who was particularly pleased with the time we had managed to save. We have subsequently been invited to carry out further works within the facility thanks to the good impression we made during this project.

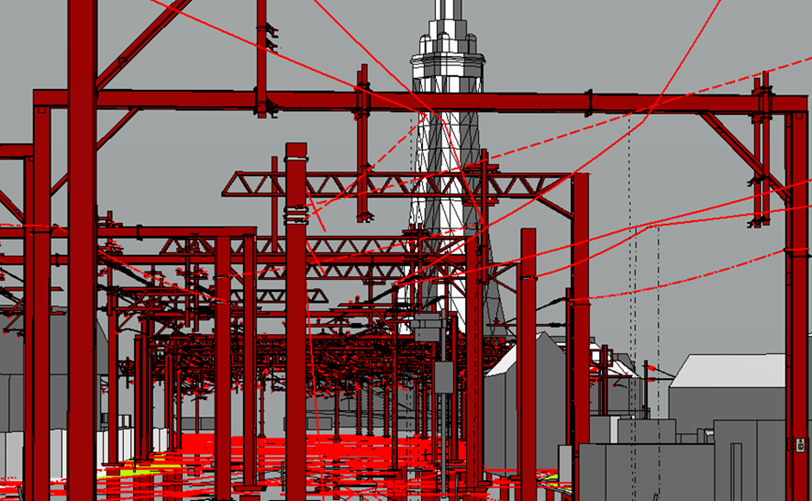

Project Description

Bombardier had a requirement to electrify the P-Line of the test track within their Litchurch Lane train manufacturing facility in Derby. We carried out the installation of the OLE foundations. The project was made particularly challenging due to working in an operational manufacturing environment and in an extremely congested site.

Project Details

- Client: VolkerRail

- Category: Overhead Line Electrification